Paper Mill Waste Recycling Solution

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- Apr 5,2018

Summary

With the raising awareness of protecting forest and grass, most paper mills choose to recycle waste paper as raw materials to produce paper. Various waste paper can be used to remake paper, like carton box, office documents, cardboard for package.etc. A report shows that a recycled paper mill with an annual output of 1 million 500 thousand tons will produce 180 thousand tons" paper making waste residue" a year.

Great Value Exists in the Paper Mill Waste Recycling

With the raising awareness of protecting forests and grass, most paper mills choose to recycle waste paper as raw materials to produce paper. Various waste paper can be used to remake paper, like carton boxes, office documents, cardboard for packages, etc. A report shows that a recycled paper mill with an annual output of 1 million 500 thousand ton swill produce 180 thousand tons" paper making waste residue" a year. As there are some plastic, mental, and grits in the waste paper, taking advantage of these kinds of waste to remake fuel is the other potential business for the paper mill.

Waste Produced in the Process of Paper Remaking

Normally used paper will be packed by wires via compactor and then transferred to the paper mill.

Most of the used paper will dissolve in the process of manufacturing pulp, the rest of metal wires and plastic will be curled together. That’s where the ragger wire and ropes come from.

Difficulties of Paper Mill Waste Recycling

Lots of mixed paper mill waste which is difficult to dispose by manual

Derivatives produced in the process of paper remaking are highly difficult to be processed

Features of Harden One-stop Paper Mill Waste Recycling

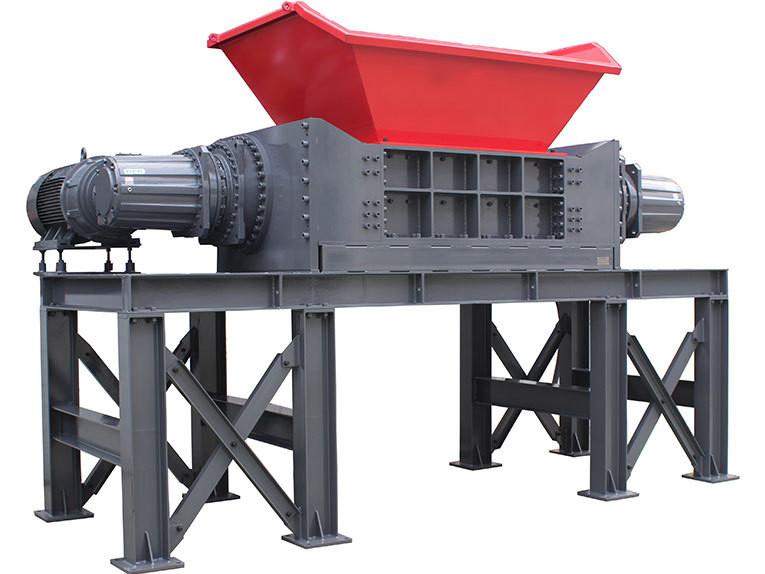

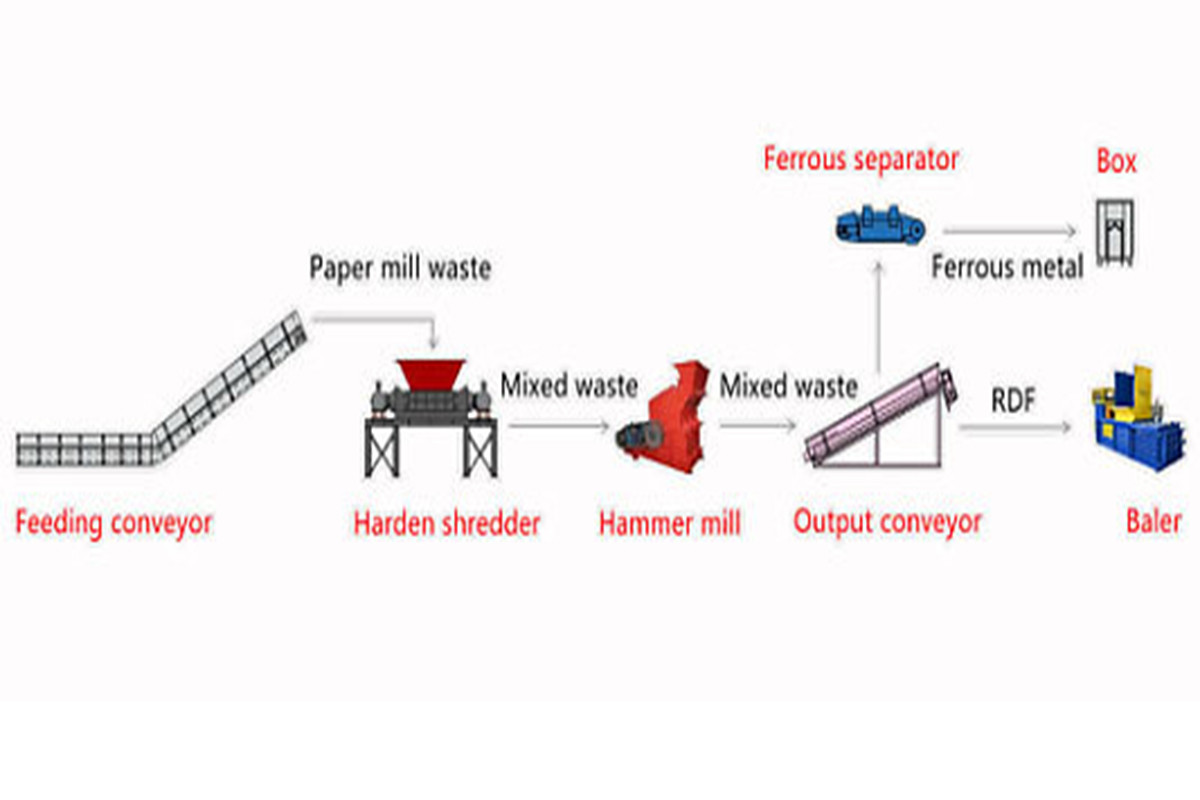

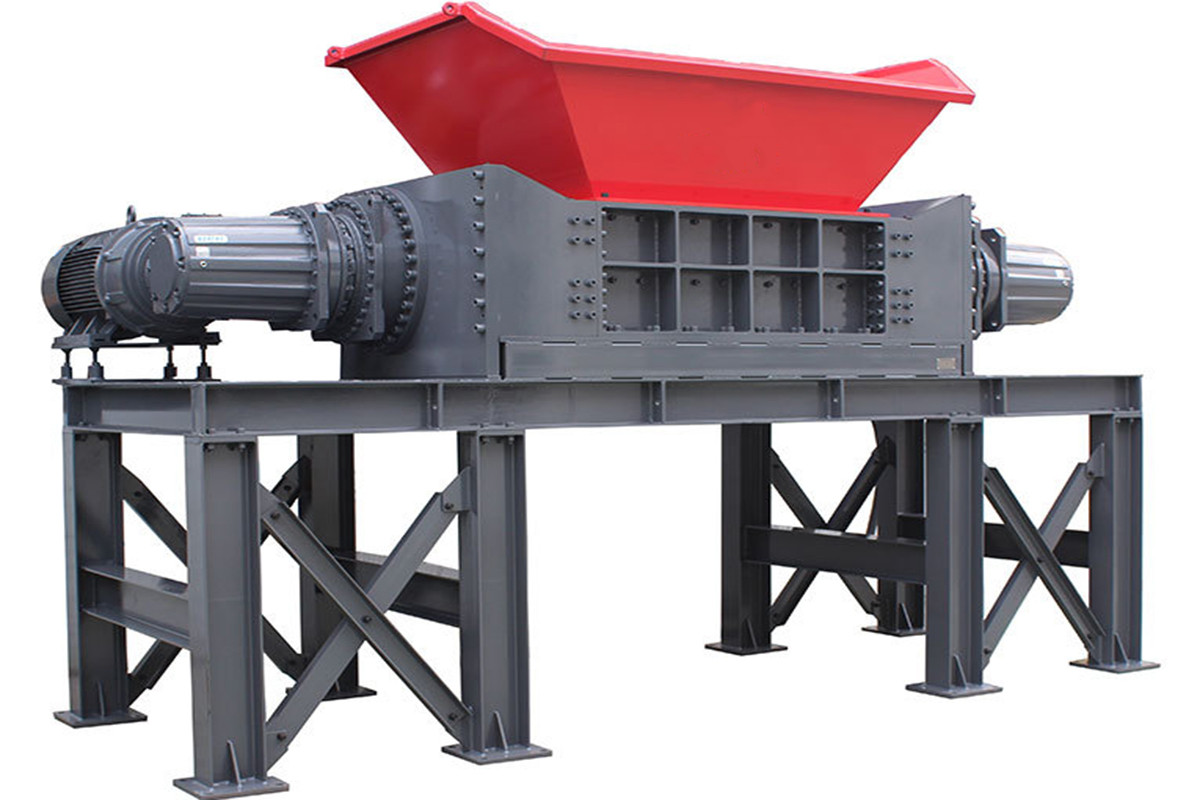

Harden has developed a one-stop paper mill waste processing system, including the ragger wire shredder, hammer mill, and ferrous separator. This kind of system is prevalent in the market, harden one-stop paper mill waste processing has received thousands of successful cases since released.

Chain conveyor+Harden Shredder+HammerMill+ Ferrous Separator

v Conveyortransport for labor reducing

v Lownoise, dust, and knives wear

v Selfdischarging ferrous separators

v Automaticcentral controller for safe and easy operation

v Horizontalpacking machine saves transport and loading cost

Benefits of Harden's One-stop Solution for Paper Mill Waste Recycling

High efficiency

1-10 tons of waste paper can be disposed of per hour

96% of the plastic, metal wire can be separated

Metals recovery, RDF(Plastic)production

Reducing

Solve the unrecyclable problem

Reduce the landfill space

Economical

High-quality automatic system lowers the labor cost

Quality machines save cost on maintenance

Save transportation cost

Parameters of Paper Mill Waste Shredder TD912

|

Model

|

TD912

|

|

Motor power (KW)

|

75+75

|

|

Cutting chamber (mm)

|

900*1200

|

|

Cutter size (mm)

|

Φ460*50

|

Quantity of blades (mm) | 20 |

Hopper opening (mm) | 2000*1400 |

Machine dimension (mm) | 4500*2200*2800 |

Machine weight (Kg) | 10000 |

Throughput (tons/h) | 1-2 |

Video

Title