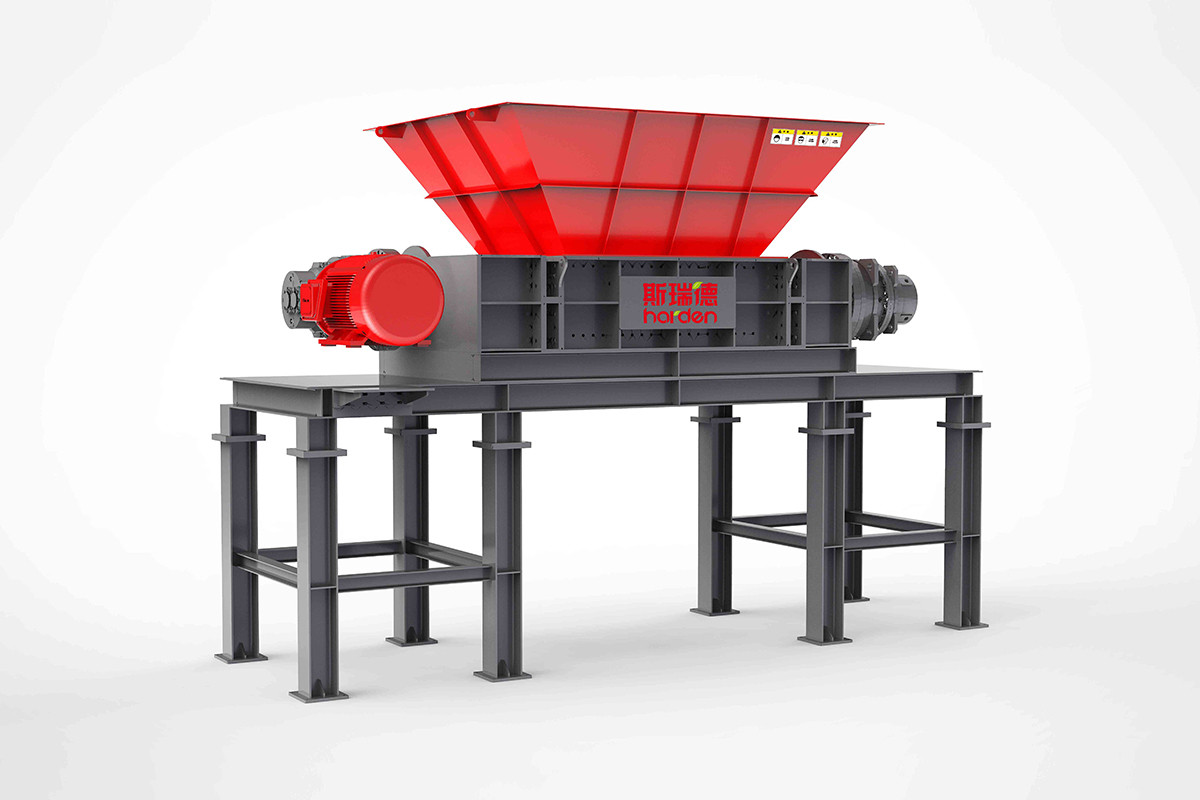

General Solid Waste Shredder—Shearing-Type Shredder

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- Jan 10,2021

Summary

The double shaft shredder is especially used for wood, waste plastic, waste rubber tires, bulky waste, municipal solid waste, medical waste shredding.

For solid waste

pretreatment, solid waste shredder is required to have the advantages of high

throughput, low power consumption, wide material adaptability, and low noise. These

requirements limit the application of hammer crushers, impact crushers, jaw

crushers, antiroll crushers, and cone crushers for solid waste treatment,

especially for municipal solid waste. The shearing type shredder can

disassemble large solid waste into 20-50mm diameter fragments, which can be

used for the pretreatment of solid waste such as waste plastics, waste rubber tires,

organic waste, wood pallet, bulky waste, MSW, and so on.

WHAT IS A SHEARING-TYPE SOLID WASTE SHREDDER?

The shearing type shredder

is the most commonly used shredder in the solid waste treatment industry, mainly

relies on the principle of cutting and shearing to complete the

process of solid waste shredding, can be used for wood, plastic, tires, metal,

domestic waste, and other material.

THE MAIN

STRUCTURAL COMPONENTS OF SHREDDER:

(1)

Cutter

plate: shreds the material

(2)

Fixed

knife: anti-blocking

(3)

Cutter

shaft: combines with cutter plate

(4)

Cutting

chamber

(5)

Support

frame

(6)

Drives

(hydraulic or motor)

(7)

Power

transmission structure

(8) Control system

ADVANCED TECHNOLOGY FOR CUTTER CLEARANCE

The most problem with shearing type shredder is that the cutter clearance between cutters is fixed.

It’s difficult for mixed waste shredding because a great deal of cutting force

is required in the shredding process of large material. If the cutter clearance

is adjusted, the relatively thin waste will be squeezed in the clearance, or

even wound on the shaft. When the clearance is adjusted to small, the large

material crushing is very laborious, and the friction energy consumption is

relatively high. The only way to solve this awkward situation is to increase motor

power, which can easily damage the cutter and increase energy consumption.

Harden continues to research and develop technology to provide customers with

the best cutter clearance solution.