Single Shaft Shredder Makes High Production Capacity and Small Discharge Possible

- Share

- publisher

- Harden Machinery Ltd.

- Issue Time

- Jan 13,2023

Summary

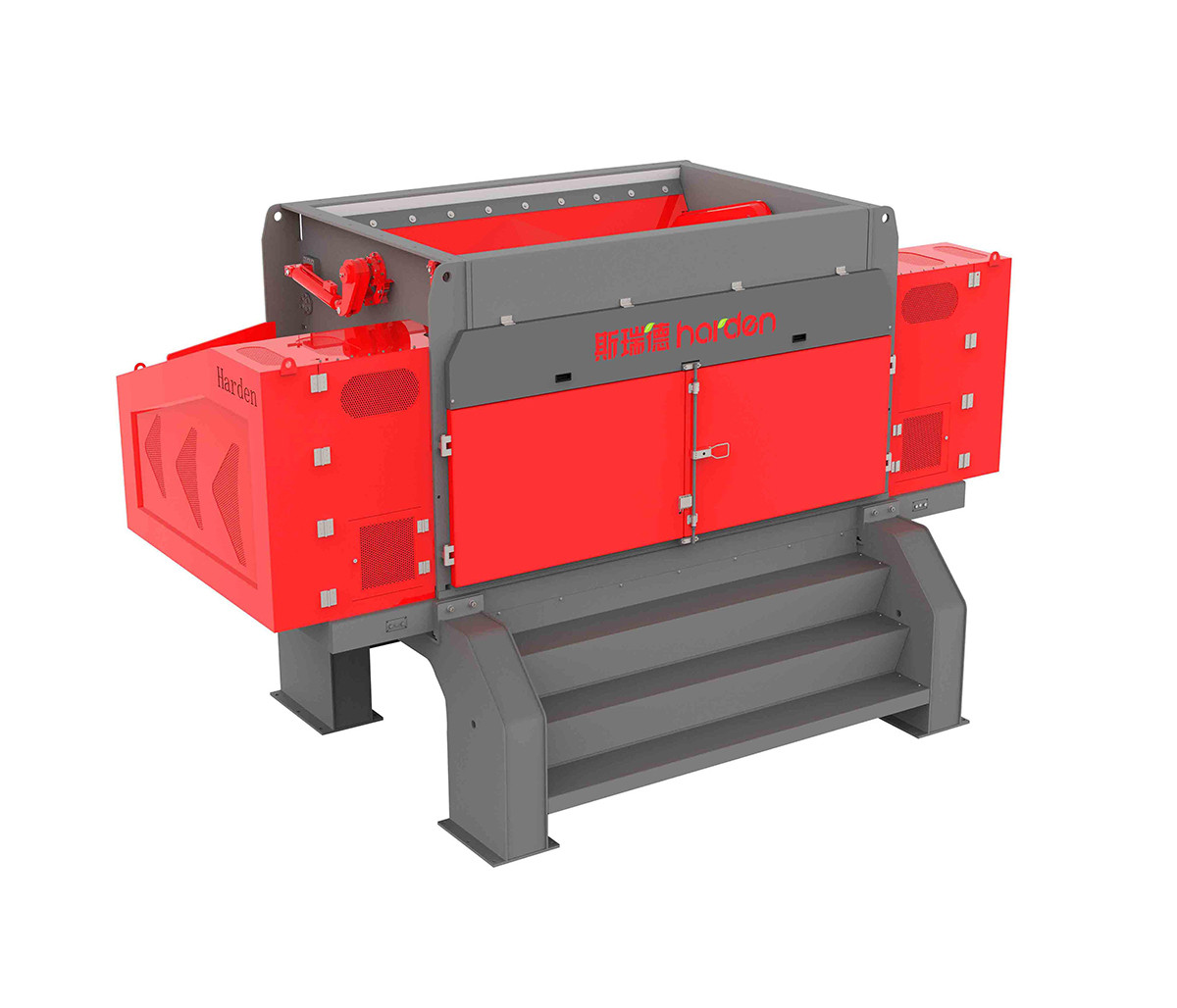

According to different material properties and shredding requirements, different types of shredders will be selected, such as single shaft shredder, double shaft shredder, primary shredder, and four shaft shredder. Each shredder has its own suitable application field. As a representative of high production capacity and small discharge size, single shaft shredder is well recognized by customers.

According

to different material properties and shredding requirements, different types of

shredders will be selected, such as single shaft shredder, double shaft

shredder, primary shredder, and four shaft shredder. Each shredder has its own

suitable application field. As a representative of high production capacity and

small discharge size, single shaft shredder is well recognized by customers.

This article will introduce the application range of single shaft shredder and

how to achieve high capacity and small discharge size.

First

of all, the baled or bulk material can be put into the cutting chamber of the

single shaft shredder. When the cutter shaft rotates, the cutters installed on

the shaft will continuously shred the material, and the hydraulic feeder push will

control the pushing state autonomously according to the shredding situation.

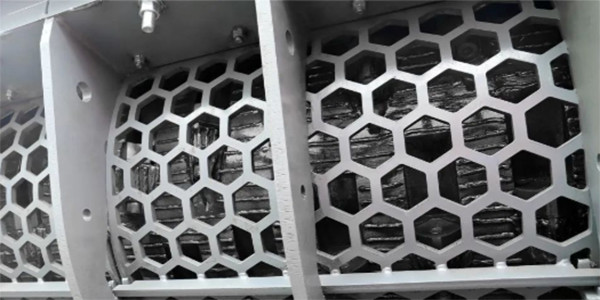

The input material will be shredded into small particle size fragments in the

continuous shredding process. The waste will drop down when the particle size

is smaller than the mesh size of the perforated screen, which means that the whole

crushing process is completed.

The

core technology promises high production capacity and small discharge size

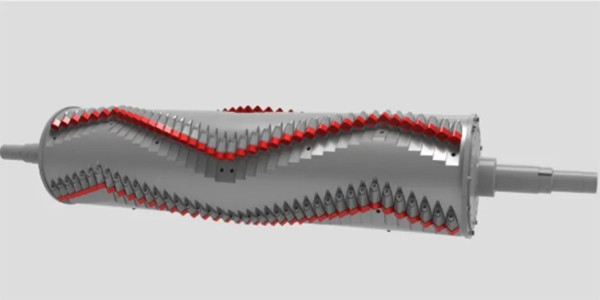

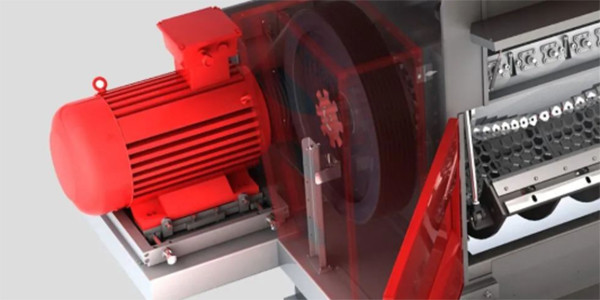

In

order to achieve the purpose of high production capacity and small discharge

size, Harden’s single shaft shredder adopts dense cutter arrangement type,

intelligent pressing technology, adjustable perforated screen and other

technologies, and the strong power system ensures the smooth operation of the

equipment. When foreign objects enter the cutting chamber, the shredder will

stop in time, and the staff can check the problem through the hydraulic

maintenance door to avoid cutter damage.

The application of single shaft shredder

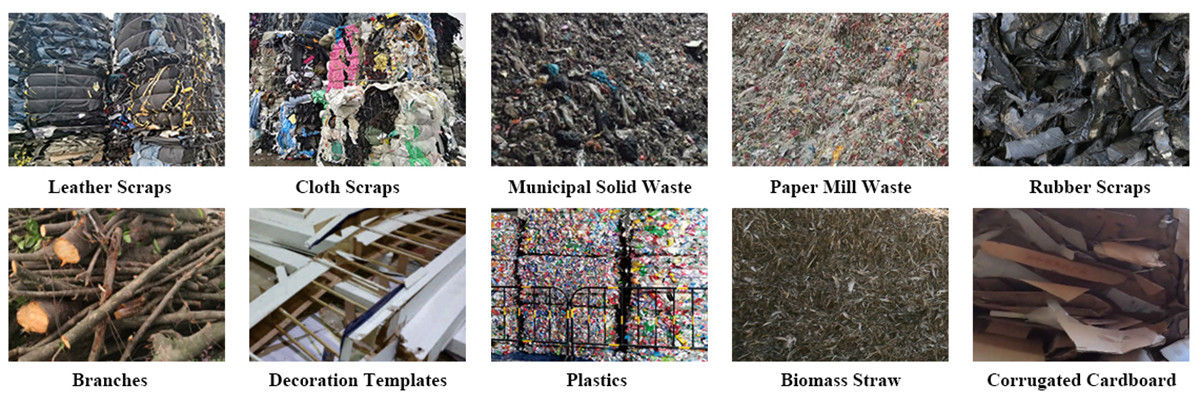

Single

shaft machine has a wide range of applications, whether it is flexible and high

strength materials, or low density of light substances, it can run smoothly.

Application include leather scraps, cloth scraps, municipal solid waste, paper

mill waste, rubber scraps, branches, decoration templates, all kinds of

plastic, film, biomass straw, corrugated cardboard, and so on.

If

you have any shredding requirement or want to know more about single shaft

shredder, please feel free to contact us and we are willing to help you.

Video