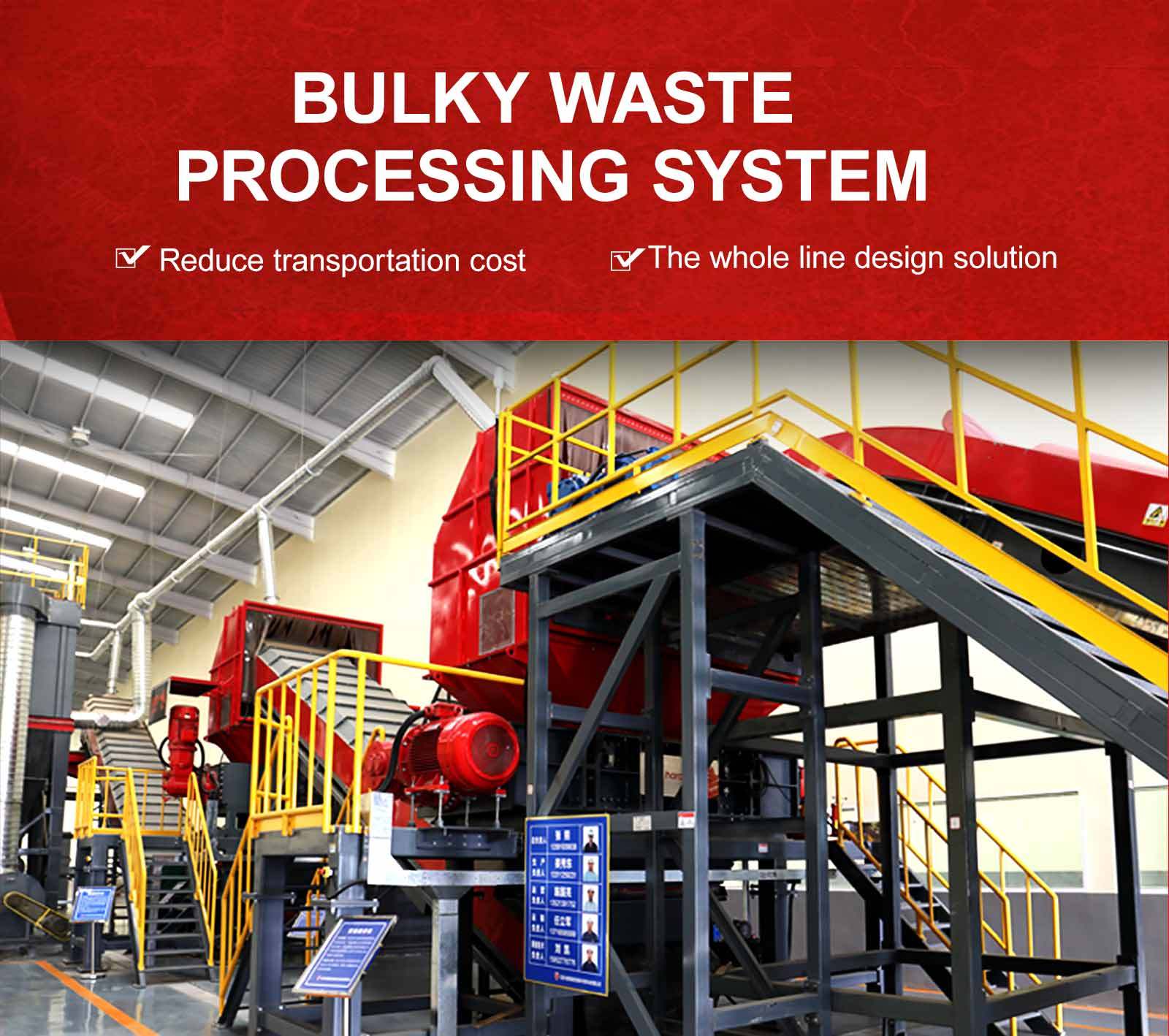

Bulky Waste Shredding Disposal

- Share

Types of Bulky Waste

Bulky waste might be too large to be handled by nature, but it is far too valuable to be left unutilized. Objects that are awkwardly sized and heavy – for example furniture, mattress, large devices and appliances, are traditionally classified as bulky waste. These Large objects cause headaches in transportation, and moving them around is often expensive.

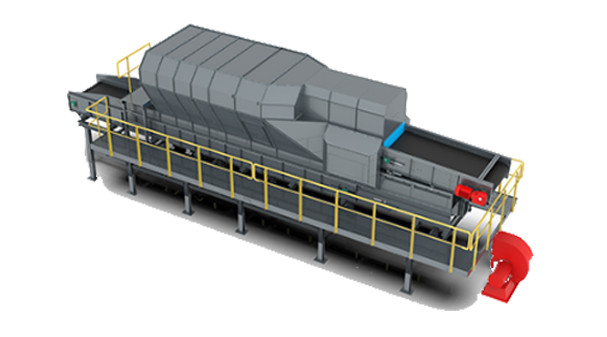

Method of Processing Bulky Waste

Pre-shredding bulky waste enables loading the material compactly, which cuts transportation costs. With a smaller gain size, the waste is more efficient to process: screening and sorting can be done more accurately, and different materials are faster in their own stacks and continue to the recycling processes.

Harden has launched a special shredder for bulky waste, providing the market with excellent bulky waste processing system equipped with double shaft shredder or primary shredder. The feeding mode can be selected as grab feeding, chain conveyor feeding or dumping directly from vehicle. Magnetic separator can also be equipped in the discharge side which is connected to the stock bin, compression vehicle or ordinary truck.

#Appliance scrap shredder #Refrigerator recycling

The system is mainly suitable for the classification and resource utilization process of bulky waste such as mattresses, and sofas. Through the two-stage shredding processes of the double-shaft shredder and four-shaft shredder, the discharged material will go through fine processing treatments such as wind separation, magnetic separation, and granulation, etc, the metal included in the bulky waste will be separated with the combustible material. which can be produced into RDF, realizing the maximum utilization of resources.

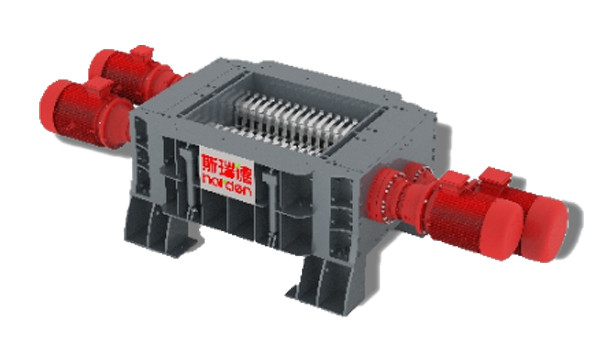

Double Shaft Shredder

Stable operation / Imported knives from Europa, with low maintenance cost

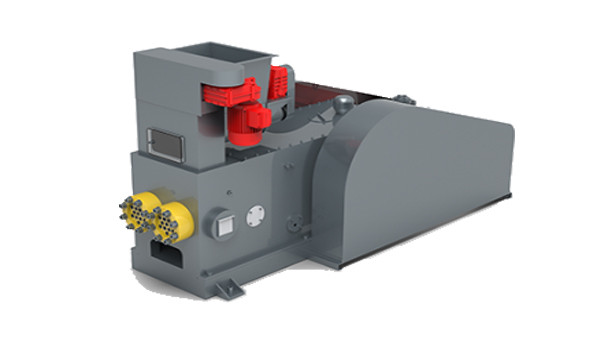

Hydraulic Driven Primary Shredder

Large effective shredding space / Unique running programs aim at different kind of material

Four Shaft Shredder

Overloading protection / Customized discharging, with homogeneous size

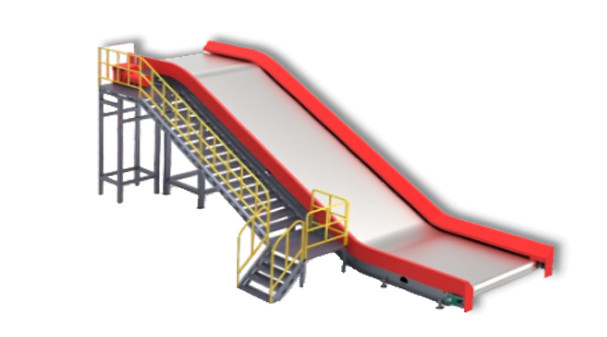

Slat Conveyor

Anticorrosive material / Remote start or stop, emergency stop or overloading control

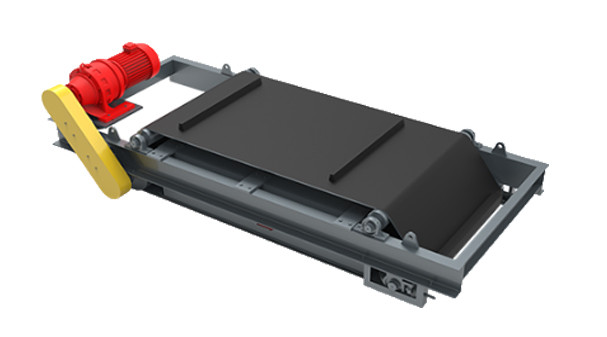

Magnetic Separator

Removing metal effectively / Enclosed space to prevent the leakage of the dust

Dust Separator

Collecting dust which is produced from the system to improve the working environment

Air Separator

Effectively sorting combines with gravity and the strength of wind, replacing manual sorting

Granulator

Squeezing the material into high-density RDF particle, with customized size

|

Model

|

TD612

|

TD912 | TD1216 |

TPH1620

|

TPH1826

|

TDH912(Hydraulic driven) | TDH1216(Hydraulic driven) | ||||

Motor power (KW) | 45X2 | 75X2 | 90X2/32X2 | 160/200/250 | 250/160X2 |

75/132/160 | 200/160X2 |

||||

|

Rotating speed (RPM ) |

14-20

|

11-20 | 10-20 |

16.5-67

|

17-45

|

6-16 | 7-21 | ||||

Dimension of the cutting chamber (AxB) (mm) | 650X120 | 900X1200 | 1200-1600 | 1600-2000 | 1600-2000 |

External dimension (L*W*H) (mm) | 4390X2180X600 | 5100x2800x3200 | 5900x3700x3500 | 4400x2100x1060 | 5000x2350x1200 |

4200x1700x3200 | 4600x2000x3200 |

||||

Knives qty (pcs) | 40/20 | 40/20 | 26 | 14/18 | 14/18 |

20 | |||||

Capacity (t/h ) | 3-20 | 3-30 | 15-50 | 30-50 | 40-80 |

2-9 | 8-30 |