Paper Mill Waste Processing System

- Share

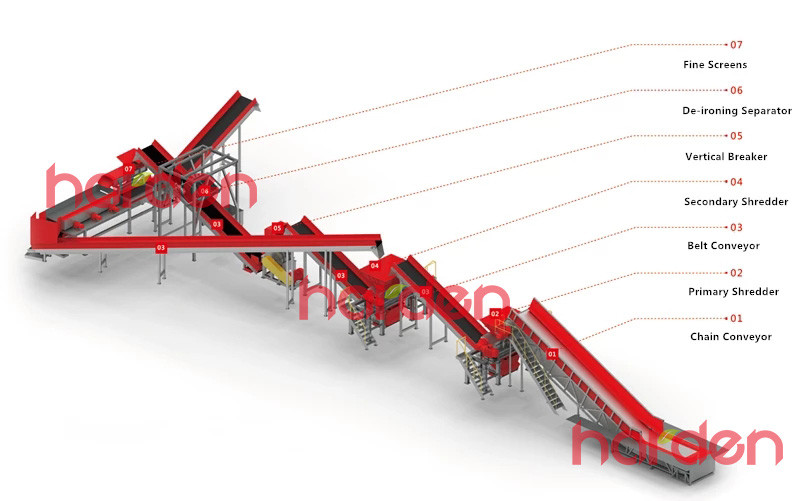

The display of core equipment

Double shaft shredder

Stable operation condition / Imported high

strength alloy knives / Low maintenance cost

Belt conveyor

Anticorrosive

material / Intelligent control function of start & stop, emergency stop,

etc.

Disperser

Fully disperses the material

Slat conveyor

Anticorrosive material / Intelligent

control function of start & stop, emergency stop, etc.

Screens the material based on the size / Imported

polymeric composite

Magnetic separator

Effectively removes the metal / Enclosed

space to avoid the leakage of the dust

Electrical control system

Automatic

operation / Sound-light alarm and fault visualization / Intelligent reminder

Remote data analysis

Central database / Automatic expert system

for fault diagnose / Information reminder

Selected cases

Paper

mill waste processing line, Zhejiang, China

Video