“New Fuel” for Paper Mill Thermoelectric Boiler!

- Share

- Issue Time

- Feb 14,2025

Summary

What is a more economical and environmentally friendly way to dispose of paper mill solid waste?

Preparing paper mill solid waste for refuse-derived fuel (RDF) is a good choice for resource utilization.

What is a more economical and environmentally friendly way to dispose of paper mill solid waste?

Preparing paper mill solid waste for refuse-derived fuel (RDF) is a good choice for resource utilization.

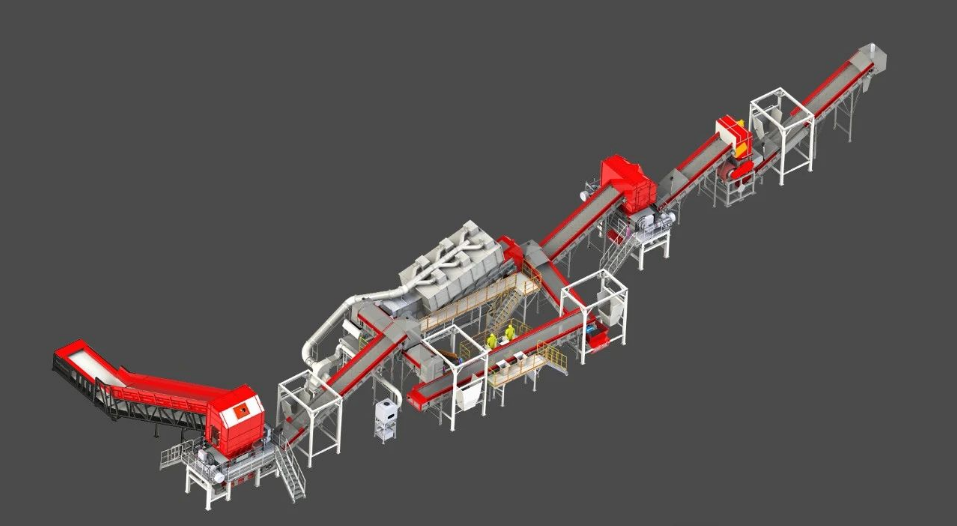

Concerning the characteristics of paper solid wastes including light residue and pulper rope, combined with the cutting-edge technology of solid wastes, Harden Machinery Ltd. puts forward the economic cycle model of “paper-making- paper wastes production (light residue/pulper rope)-RDF alternative fuel preparation technology -New fuel for thermoelectric boiler industry”.

The light residue and pulper rope are prepared into RDF alternative fuel, which replaces the traditional fossil fuel for the boiler of the paper industry's cogeneration plant.

It aims to form a circular economy ecology of self-production and self-utilization of paper mill solid waste.

The RDF alternative fuel preparation system for paper mill solid waste separates non-combustible materials and impurities from the solid waste through the preparation technology of “crushing, magnetic separation, air separation, sorting and dust removal”.

It finally obtains high calorific value RDF alternative fuels with a discharge size of about 50mm and an impurity removal rate of more than 95%.

What economic and ecological benefits can be brought to paper-making enterprises?

① Economic Benefits

RDF alternative fuel has a lower cost per unit calorific value.

As we all know, paper enterprises are large consumers of electricity. Medium-sized packaging paper enterprises annual power consumption is in the hundreds of millions of kWh, so large paper enterprises generally have their own thermal power plant.

However, with the changes in the coal market, the fuel cost share of paper cogeneration plants has been climbing.

The use of paper solid waste as raw material for the preparation of RDF alternative fuels, a calorific value of about 4000 calories, about two-thirds of the standard coal, the theoretical unit calorific value of the replacement rate can reach more than 66%.

Zero cost of solid waste in paper mills also saves high solid waste waste disposal costs.

As a result, the greater the percentage of RDF alternative fuels used in the boilers of a cogeneration plant, the lower the unit calorific value cost of the paper mill's power and heat generation.

② Ecological benefits

Resourceful and harmless treatment of paper mill solid waste refuse

RDF alternative fuels can improve energy efficiency

RDF alternative fuels have lower carbon emission reductions

Paper mill waste as an auxiliary fuel in the production of thermoelectric power not only transforms industrial solid waste into a resource of value but also relieves the region of the daily demands of resourcing and harmlessly disposing of industrial waste.

The quantitative use of RDF alternative fuels in place of traditional fossil fuels can not only significantly increase the level of energy efficiency of standard coal, but also the solid waste RDF has a lower carbon emission factor compared to fossil fuels.

Among them, the carbon emission of paper mill solid waste RDF is only 30% of coal, which can effectively reduce the carbon emission of paper enterprises.

Paper Mill Solid Waste RDF Preparation Projects

Paper mill solid waste prepared into RDF alternative fuel, not only reduces the dependence on fossil energy, but also effectively promotes the traditional high-polluting industries to achieve the goal of pollution reduction, carbon reduction, energy saving and efficiency, bringing about multiple effects of environmental quality improvement and industrial development.

What's more, It accelerates the green transformation of economic structure, enhancing the core competitiveness of paper enterprises, and boosting the paper industry to achieve high-quality development.