Construction and decoration waste resource recovery system

- Share

Construction and decoration waste is produced in the process of interior decoration in urban areas, mainly from construction sites and residential areas. The components from the waste are complex, e.g. glass product, packaging, gypsum board, cement, metal, plastics product, wood board, rubber, etc.

The annual output of construction and decoration waste is basically equivalent to that of municipal solid waste (the national annual output of construction and decoration waste ranges from 1.55 billion tons to 2.4 billion tons). Most of its waste are recyclable material, but because of its complex components, it is difficult to classify and separate.

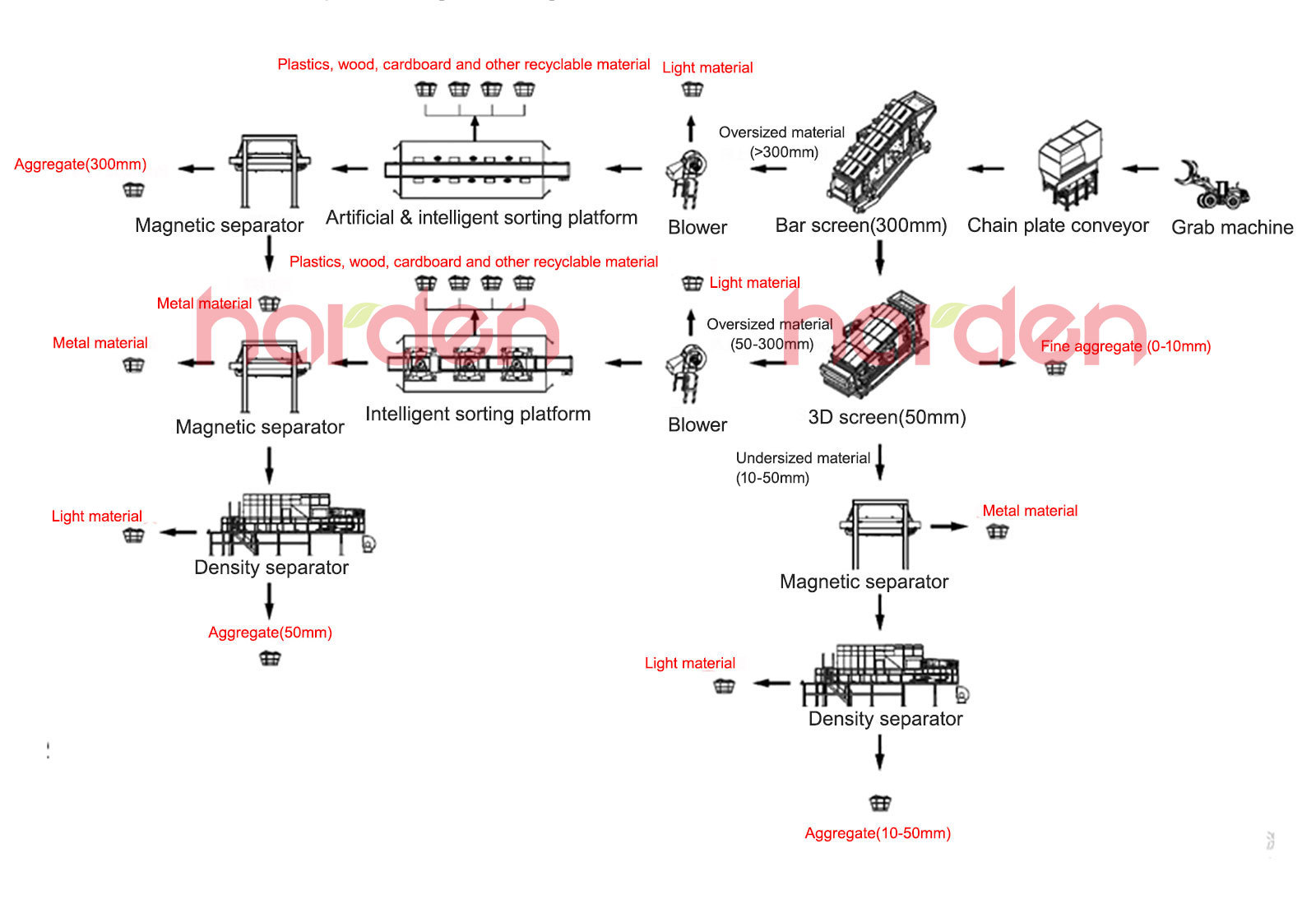

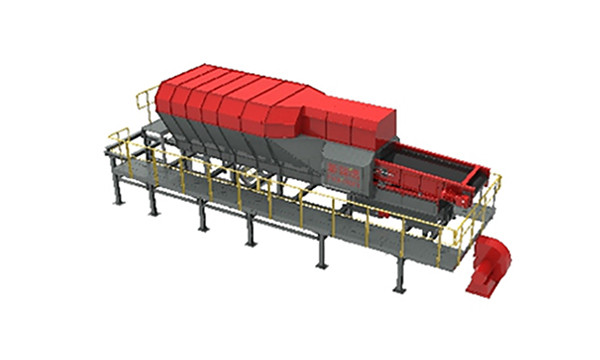

The processing flow diagram of construction and decoration waste

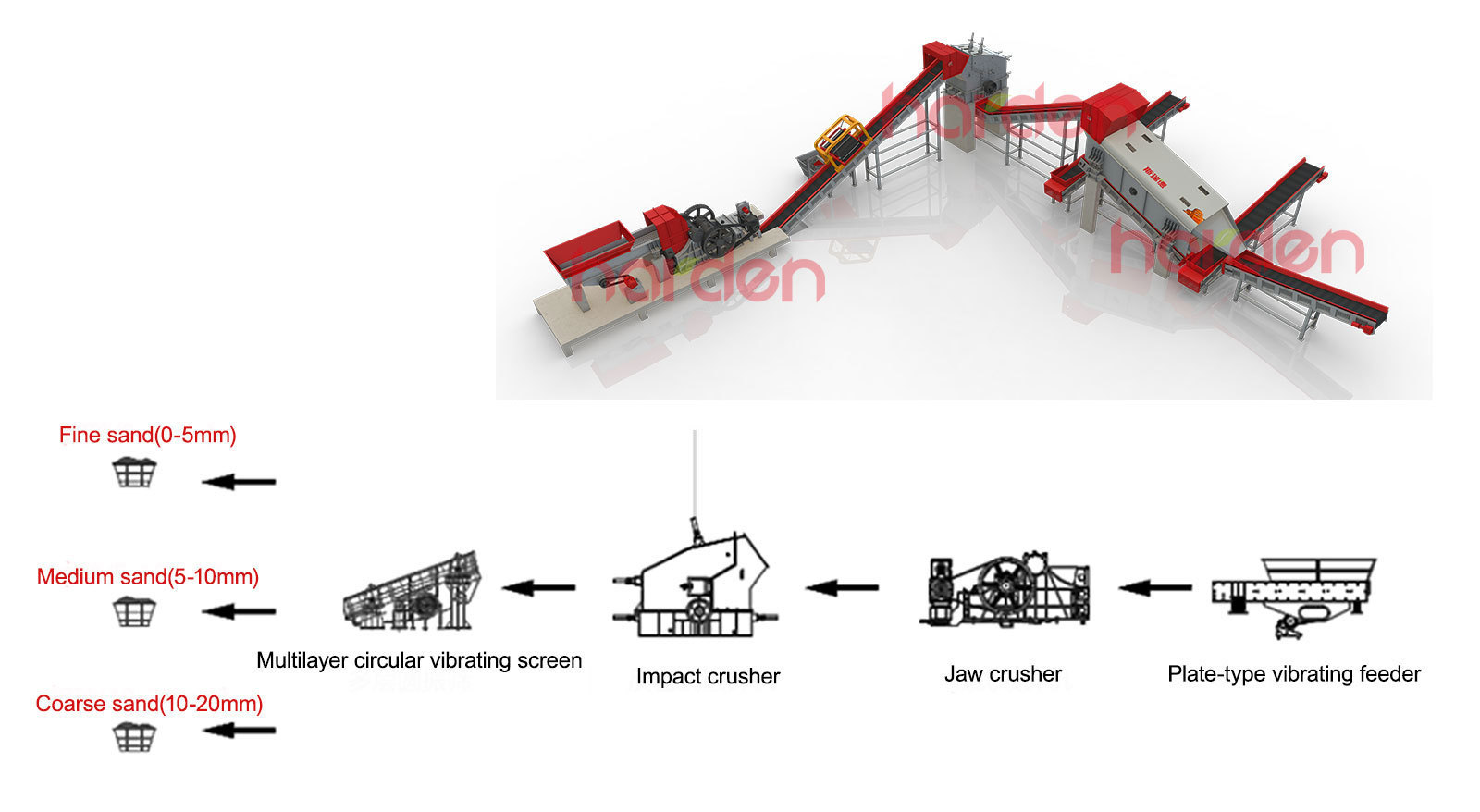

The processing flow diagram of sand making with recycled aggregate

Stone brick

Plastics

Wood material

Metallic conduit

Cardboard

Stainless steel alloy

Gypsum

Concrete block

Screening effect

Before screening

Material after screening: waste metal

Material after screening: 0-10mm aggregate

Material after screening: 50mm aggregate

Material after screening: light fuel

Resource profit maximization

The concrete block, sand and stone brick can be recycled as powder, fine aggregate and coarse material, etc. Metal, aluminum and copper can be used in metal recovery and re-refining. Wood material and cardboard canbe used as raw material for organic matter ,so that to recue waste ofresources.

Different from the single operation mode in which the landfill collects waste treatment fee, the decoration waste pretreatment line can sell the recycled aggregate and metal as product to enterprises which need the material, so that to earn profit and maximize the profit from resources.

Energy saving is reflected in two points. Firstly, the energy consumption of metal and aggregate recycling is far less than the consumption of metal smelting, sand mining and manufacturing. Secondly, RDF fuel can be contained from decoration waste to replace coal and save energy. Harden offers a complete solution for preparing RDF fuel.

Most of the decoration waste will be recycled after the preliminary sorting, which reduces the encroachment on the land and the environmental problems caused by the waste combustion to the greatest extent.

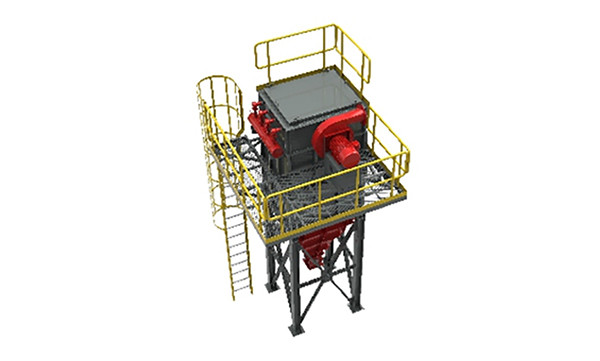

Bar

screen

Screens different size material / Short maintenance

duration / High wear resistance

3D

screen

Multilayer structure design ensures

screening size / Convenient installation

Density

separator

Simple structure design / Adjustable outlet

angle and air volume / Negative pressure suction

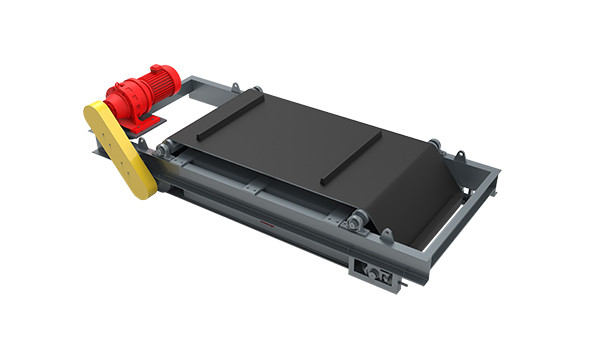

Magnetic

separator

Effectively removes the metal / Enclosed

space to avoid the leakage of the dust

Dust

separator

Effectively removes the dust, with

excellent sealing performance and low energy cost

Intelligent

sorting platform

Robot sorting / Well-adapted

Workshop

diagram