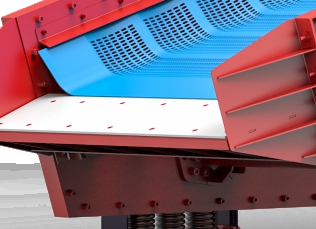

Flip-flow Screen

- Model

- SZS-F1652

Review

Description

Flip-flow Screen

According to the principle of mechanical vibration, a single drive is used to generate dual vibrations, so the dynamic screen plate obtains extremely high acceleration through tension and relaxation deformation.

lt is suitable for difficult-to-screen materialsespecially materials with high wet viscosity that are prone to clogging and jamming. The flexible screen plate and relaxation efficiency have powerful screening and anti-blocking performance.

Product Parameter

|

Model

|

SZS-C1652

|

|

Power (KW)

|

45

|

|

Screening Area (mm)

|

1600*5200

|

|

Machine Dimension (mm)

|

6800*3600*2100

|

Machine Weight (t) | 6.7 |

Capacity (m³/h) | 20-25 |

Product Features

Dynamic Flip-flow Plate

According to the material characteristics, vibration parameterscan be quickly adjusted on site.

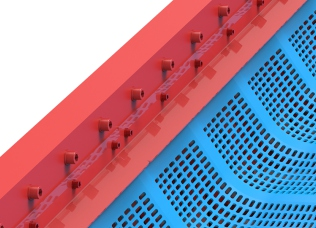

Optional Multi-layer Design

According to actual screening requirements, double-layer or even multi-layer relaxation screens can be customized to achieve a variety of particle size classifications.

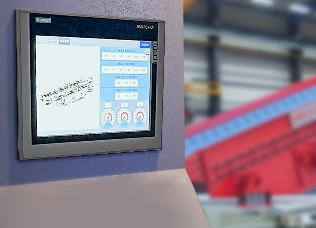

Smooth Start And Stop

Minimize start-stop shaking and reduce instantaneous impact on the screen machine and foundation. At the same time, the starting current of the motor is limited to reduce the power supply pressure of the factory.

Dynamic Flip-flow Plate

The relaxation-moving screen has anacceleration that exceeds that of traditional screen machines, effectively prevents clogging and adhesion,andhas a strong self-cleaning effect. lt is especially suitable for fine screening ofdifficult-to-screen materials.

Modular design

The screen is fixedwithout screwsand the quick-release design allowsfor rapid on-site replacement ofmodular structural components which facilitates maintenance and replacement and can be flexibly adjusted according to the productionline.

Performance optimization

Special instruments are used to detect and adjust various performance indicators before leaving the factory to ensure that the equipment reaches optimal operating status.

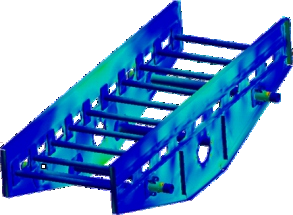

Structural optimization

The reinforced screen machine structure improves vibration fatigue life and overall reliability. The finite element method is used to make the structural design more reasonable, avoid resonance, and have better stability.

Diluted oil lubrication

The exciter bearing adopts double sealing and diluted oil lubrication, which effectively extends the bearing life and makes maintenance easier.

Convenient adjustment

According to material characteristics, vibration parameters can be quickly adjusted on-site

Optional Multi-layer Design

According to actual screening requirements, double-layer or even multi-layer relaxation screens can be customized to achieve a variety of particle size classifications.

Smooth start and stop

Minimize start-stop jitter and reduce instantaneous impact on the screen machine and foundation. At the same time, the starting current of the motor is limited to reduce the power supply pressure of the factory.

Typical Application Range

Construction Waste

Waste Battery

MSW

Waste Plastic

Industrial Waste

Biomass Waste